In the world of rapid diagnostics and point-of-care testing, lateral flow technology has become indispensable — especially after the global spotlight on COVID-19 testing. One of the key components that make lateral flow tests efficient and accurate is the lateral flow dispenser. It may sound technical, but its role is crucial: precisely dispensing reagents during test strip assembly to ensure consistency and accuracy in results.

In this article, we’ll explore what a lateral flow dispenser is, how it works, why it’s important, and what to consider when selecting the right dispenser for your manufacturing needs.

What Is a Lateral Flow Dispenser?

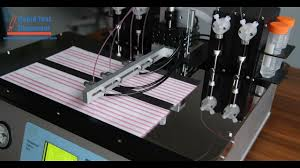

A lateral flow dispenser is a highly specialized piece of equipment used in the manufacturing process of lateral flow assays (LFAs), commonly known as rapid diagnostic tests. These dispensers accurately apply reagents like antibodies, antigens, enzymes, or other biological markers onto various parts of the test strip — typically the conjugate pad or nitrocellulose membrane.

Precision is the name of the game. Even the slightest deviation in line thickness, flow volume, or placement can affect test performance. That’s why an automated lateral flow dispenser plays a vital role in ensuring:

- Reagent uniformity

- Repeatable, high-speed manufacturing

- Improved sensitivity and specificity of tests

- Reduced wastage and production cost

These dispensers are typically used in the production of diagnostic kits for infectious diseases, pregnancy, fertility, drugs-of-abuse, food safety, and veterinary testing.

How Does a Lateral Flow Dispenser Work?

The basic principle of a lateral flow dispenser involves delivering controlled volumes of a reagent solution in precise lines across the surface of a membrane or pad. Here’s a breakdown of how it works:

1. Fluid Delivery System

- Utilizes syringe pumps, peristaltic pumps, or pressure-based systems

- Delivers a consistent and controllable volume of liquid reagent

2. Nozzle/Head Assembly

- Multiple dispensing heads can be used to apply several reagents simultaneously

- Adjustable height, speed, and spacing for different types of membranes and patterns

3. Motion Control System

- Motorized X-Y-Z axes or conveyor belts guide the membrane or the dispensing heads

- Ensures even, uninterrupted movement during dispensing

4. Drying & Stabilization

- After dispensing, membranes may pass through drying ovens to fix the reagents

- Enhances shelf life and test accuracy

Automation ensures repeatability and eliminates human error — critical for high-volume diagnostic kit production.

Key Features of a Modern Lateral Flow Dispenser

When you’re investing in a lateral flow dispensing system, here are the top features to look out for:

- High Precision Line Dispensing (typically within ±2% CV)

- Adjustable Flow Rates and Speeds

- Multiple Channel Capability (for simultaneous reagent dispensing)

- Compatibility with Various Membranes (e.g., nitrocellulose, glass fiber)

- User-Friendly Software Interface

- Minimal Reagent Waste

- Compact and Scalable Design for lab or industrial use

Some high-end dispensers even include real-time vision systems to detect and adjust misalignments on the fly.

Where Is a Lateral Flow Dispenser Used?

Lateral flow dispensers are a key part of diagnostic kit assembly lines across several industries:

🧪 Medical Diagnostics

- Infectious disease tests (COVID-19, HIV, malaria, etc.)

- Cardiac markers

- Hormone level tests

🐄 Veterinary Testing

- Pathogen detection in livestock and pets

- Food safety monitoring

🧫 Environmental Testing

- Water contamination

- Soil and air quality screening

🍏 Food & Beverage Safety

- Detection of allergens, toxins, or bacteria in food products

👩🔬 Research & Development

- Prototyping and quality testing of new diagnostic tools

Benefits of Using a Lateral Flow Dispenser

Here’s why more manufacturers are upgrading from manual application to automated dispensers:

✅ High Throughput

Dispensers can produce thousands of consistent test strips daily, perfect for meeting mass-market demand.

✅ Improved Accuracy & Reliability

Precision delivery ensures uniformity in reagent volume and placement, leading to more reliable test results.

✅ Reduced Waste

Precise dispensing minimizes reagent use, reducing waste and saving costs over time.

✅ Scalable Solutions

From benchtop R&D setups to fully automated industrial systems — dispensers come in all scales.

✅ Enhanced Regulatory Compliance

Uniformity in test strip production is critical to meeting medical regulatory standards like FDA, ISO, or CE marking.

Challenges and Solutions in Lateral Flow Dispensing

While the technology is powerful, it’s not without its challenges:

❌ Clogging Nozzles

Solution: Use self-cleaning systems or optimized reagent formulations.

❌ Inconsistent Flow

Solution: Choose dispensers with pressure feedback control and robust calibration options.

❌ Reagent Degradation

Solution: Use temperature-controlled reservoirs and reduce exposure time during loading.

❌ Variability Across Membranes

Solution: Customize dispensing parameters based on membrane thickness, material, and absorption properties.

With the right dispenser and maintenance protocols, these challenges can be minimized or entirely eliminated.

How to Choose the Right Lateral Flow Dispenser

Every manufacturing environment is different. Here are a few criteria to help you select the right model:

- Volume Needs: How many strips do you need to produce daily or weekly?

- Membrane Compatibility: Does the dispenser support your chosen test strip materials?

- Number of Reagents: Will you need multiple lines dispensed simultaneously?

- Budget and ROI: Consider not just purchase cost, but savings from reduced waste and downtime.

- Support and Training: Does the manufacturer offer installation help, maintenance support, or operator training?

Working with an experienced supplier like lateralflowcassette.com ensures you get a system tailored to your production scale, quality requirements, and regulatory goals.

Real-World Example: COVID-19 Test Kit Manufacturer

During the pandemic, one diagnostic company saw a 10x increase in demand for rapid antigen tests. Manual reagent dispensing could no longer keep up, leading to:

- Test failure rates of 7%

- Worker fatigue and errors

- Inconsistent strip performance

After switching to an automated lateral flow dispenser:

- Production scaled up by 400%

- Error rates dropped below 1%

- The company achieved ISO 13485 certification within six months

This transformation underlines how crucial automation is in today’s diagnostic landscape.

Future of Lateral Flow Dispensing

The industry is evolving, and lateral flow dispensing technology is keeping pace. Here’s what’s next:

- AI-Assisted Quality Control: Automated vision systems with AI to detect strip defects

- Smart Dispensers with IoT: Real-time performance data and alerts for proactive maintenance

- Miniaturized R&D Systems: Affordable compact dispensers for startups and academic labs

- Eco-Friendly Systems: Reduced reagent use and bio-waste for greener diagnostics

Final Thoughts

In the race to deliver fast, accurate, and affordable diagnostics, the lateral flow dispenser plays a critical behind-the-scenes role. It ensures consistency, enhances test reliability, and enables manufacturers to meet growing global demand. Whether you’re an established diagnostic company or just starting to scale up production, investing in the right dispenser can drastically improve your output, efficiency, and bottom line.

To explore the best lateral flow dispenser solutions for your business, visit:

https://www.lateralflowcassette.com/